Electro Servo

ES23

Tailift’s newly launched, ES23, AC Servo drive and numerical control technology. Featured with HIGH SPEED, HIGH PRECISION, ENERGY SAVING, AND LOW NOISE. Equipped over-load protection, ES23 is an effective implement for thinner sheet metal. ES23 combined with processing abilities of PUNCHING, FORMING, ROLLER FORMING AND TAPPING, an all-in-one machine. The integration assembly reduces floor space requirements effectively. LOW ELECTRICITY CONSUMPTION, ENERGY-SAVING, ELIMINATING THE HYDRAULIC . This ECO friendly product is the major milestone for Tailift’s R&D.

Features

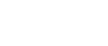

AC servo electric system

ES23 equipped with high efficient AC Servo motor with single servo crank type punch head assembly without flywheel which results in high precision, Low noise and power consumption is only half of hydraulic models. No need of hydraulic oil and worry about environmental issues. High punching speed reduces the production time and ensure cost down.

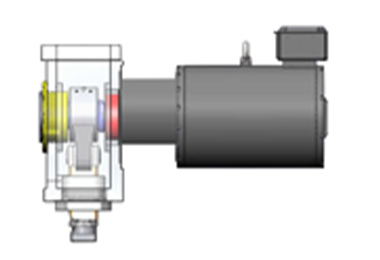

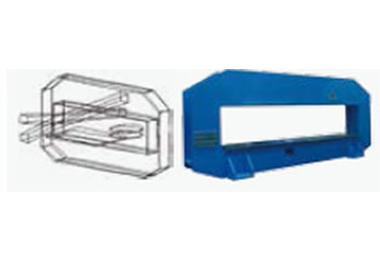

Closed O Shape Frame Structure

High Rigidity & High StabilityThe closed O shape frame structure is analyzed by the “Finite Element Analysis” software to simulate stress / strain conditions, enables the optimal structure design.

High Tensile Strength Steel ConstructionThe machine frame is welded by high tensile strength steel, which is subject to high tensile strength tests, normalization treatment and vibration stress relief so as to ensure the machine assembling accuracy.

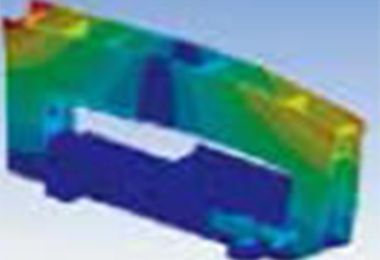

Transient State Analysis

Static Analysis

Model Analysis

Transient State Analysis

Specifications

| Item | Unit | ES23 |

|---|---|---|

| Punching Capacity | Ton | 30 |

| X axis Travel Length | mm | 2490±10 |

| Y axis Travel Length | mm | 1250±10 |

| Max Sheet Size | mm | 1250x4980 |

| Max Sheet Thickness | mm | 3 |

| Max.Sheet Weight | kg | 110 |

| X Axis Traverse Speed | m/min | 80 |

| Y Axis Traverse Speed | m/min | 70 |

| Max Traverse Speed | m/min | 105 |

| Punching Speed at 25mm pitch | hits/min. | 360 |

| Tool Type | Thick turret | |

| Max Punching Diameter | mm | 88.9 |

| Number of Tool Stations | 34 | |

| Numer of Auto Index Stations | pcs(type) | 2B |

| Turret Rotating Speed | rpm | 30 |

| Auto Index Rotating Speed | rpm | 100 |

| Ram Stroke Distance | mm | 0-31 |

| Working Table | Brush + Ball | |

| Number of Sheet Clamps | pcs | 3 |

| Air Supply | NL/min | 250 |

| Air Press | bar | 6 |

| Size of Control Cabinet | mm | 2150 x 700 x 2000 |

| Number of Controllable Axis | Axis | 4+1 |

| RAM Memory | KB | 512 |

| Serial Interface | RS232 / RJ45 / PCMCIA | |

| Punching Precision | mm | ±0.1 |

| Machine Dimension (L × W × H) | mm | 4690 x 5105 x 2110 |

| Net Weight (approx.) | kgf | 14000 |

- Specifications are subjects to change without prior notice.

- Acceleration / deceleration rate of X / Y-axis are dependent on weight of materials.

- Punch speed depends on processing conditions, stroke length, acceleration / deceleration of axes speeds.

Accessories

Standard

- Supporting Ball Set

- Anti-vibration Foot Mounts

- Sheet Distortion Sensor

- Heavy-duty Clamp

- Die Holder Brush

- Repositioning Cylinder

Optional

- CAD/CAM Software

- Tapping System

- Hard brush Table

- Block Lowering Device

- Independent Control Cabin

Station Arrangement

Turret with 34 Stations- The turret is transmitted through the worm and worm gear mechanism.

Two shafts are synchronously transmitted via a connecting rod for safe and dependable positioning. - The turret is designed with 34 stations, and accommodates various tool sizes from 1/2” to 3-1/4”. Changing tool size is available upon customer request.

- Each station can be fitted with various brand tools, such as Mate and Wilson.

- Designed with two circular track stations.

- Replaceable bushing easy to maintain.

|

|

| Atype (1/2") MAX diameter 12.75mm | 18 (14 accept shaped tools) |

| Btype (1-1/4") MAX diameter 31.75mm | 10 (10 accept shaped tools) |

| Btype (1-1/4") MAX diameter 31.75mm | 2 AUTO. INDEX |

| Ctype (3-1/2") MAX diameter 50.8mm | 2 (2 accept shaped tools) |

| Dtype (1-1/4") MAX diameter 88.9mm | 2 (2 accept shaped tools) |