LS29 Electro Servo

LS29

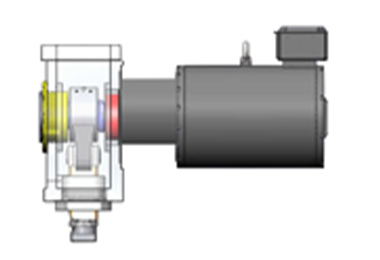

Tailift newly launched,LS29, AC Servo drive and numerical control technology. Featured with high speed, high precision,energy saving, and loe noise. Equipped over-load protection, LS29 is an effective implement for thinner sheet metal.

LS29 combined with processing abilities of punching, forming, roller cutting and tapping, an all-in-one machine. Thr integration assEmbly reduces floor space requirements effectivelu. Low avarage electrivity consumption, energy-saving,elminating the hydraulic, This ECO friendly product is the major milestone for Tailift R&D.