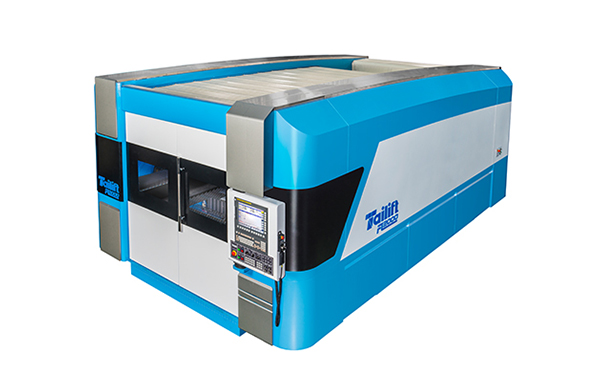

FL2000 Fanuc Series Laser Cutting Metal Machine

FL2000

- Tailift built-in operation interface.

- By Optical fiber transmission to achieve Nano Interpolation, Highest-Performance, High Speed, High Accuracy ,High Quality.

- High Efficiency : High Cutting Speed, Cost Effect, Faster Investment Recovery.

- Low Wear Down : High Thickness Sheets Processing.

- Low cutting gas consumption : Stainless Steel Sheets can processed by air also.

- Low Energy Consumption and Eco-friendly : Power Consumption is 20%-30% of Co2 Laser Cutting Machine.

- Low Maintenance Cost : no adjustments of light path, no mirror.

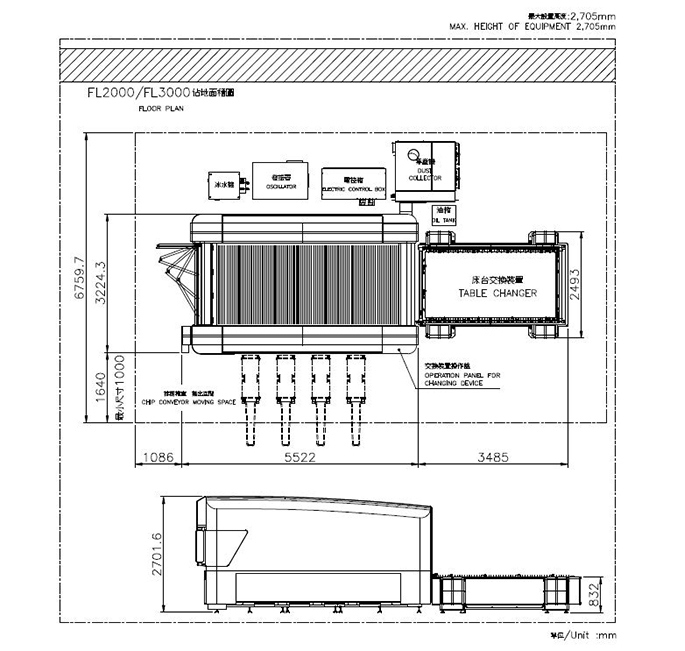

- Closed Frame Base with Gantry Type (Dual-Drive) Integrated Servo Control System to Increase Working Speed and Efficiency.

- Double Working Table Saves Loading/Unloading Time and Increase Productivity.

- High Cutting Speed at Thin Sheets and Stable Cutting at thick sheets.

- Full Covered Machine Body with OD6+ Fiber Protection Safety Glass Window Ensure the Operator Safety and Effectively controls the Laser Radiation in the Environments, Good Light Probation.

- Dust Collection System with Divided Areas: The machine is equipped with a fully enclosed splash guard for optimal machining safety. An automatic dust collection system collects dusts and waste gases in divided areas during cutting operation, ensuring a pollution-free working environment.