Hydraulic Servo

X23Plus

X23 PLUS is adapted with Germany H+L advanced Servo Hydraulic system,

Features

X23 is adapted with Germany H+L advanced Servo Hydraulic system, HPPC-30T. 30 tonnages provide more punching capacity, also the three pressure accumulators are capable of transform high/low resistance under high-speed punching capacity. Up to 450 hpm punching speed, controllable ram traverse for top/bottom dead center, favorable for processing with roller ball cutting, marking and some other special forming processing.

Servo motor with mechanical servo valve are replace the complex structure of the hydraulic servo valve, efficient reduce the maintenance cost. The excellent power-driven technology invalid energy consumption to a minimum.

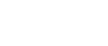

HPPC-30T hydraulic syst

HPPC-30T servo hydraulic system requires high energy only when tools in process of running throught metal sheet. Energy consumption very few in other stages. Slash area illustrates energy-saving in effect.

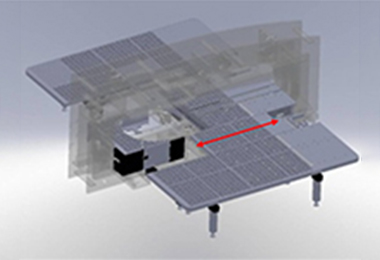

Removable Table

The table piece removed with the sheet in same speed and same direction. Protecting the sheet from friction by table.

Low block

This block raises while reposition. Protecting the sheet from scratch by reposition block.

Specification

| item | Unit | X23 PLUS | X23 | ||

|---|---|---|---|---|---|

| Punching Capacity | t | 30 | 30 | ||

| X axis Travel Length | mm | 2500±10 | 2500±10 | ||

| Y axis Travel Length | mm | 1250±10 | 1250±10 | ||

| Max.Sheet Size | mm | 1250*5000 | 1250x5000 | ||

| Max Sheet Thickness | mm | 6.35/▲3 | 6.35/▲3 | ||

| Max.Sheet Weight | kg | 110/▲70 | 110/▲70 | ||

| X axis Traverse Speed | m/min | 80 | 100 | ||

| Y axis Traverse Speed | m/min | 70 | 80 | ||

| Axes max.Traverse Speed | m/min | 105 | 128 | ||

| S=4mm孔距 25mm | hit/min | 390~420 | 400 | ||

| Nibbling Speed | hit/min | 650 | 650 | ||

| Tools Type | Thick turret | Thick turret | |||

| Max Punching Diameter | mm | 88.9 | 88.9 | ||

| Number of Tool Stations | ▲48 | 57 | ▲48 | 57 | |

| AI | 4 (2B2C) | 3 (2B1C) | 4 (2B2C) | 3 (2B1C) | |

| Turret Rotating Speed | rpm | 33 | 33 | ||

| Auto Indes Rotating Speed | rpm | 100 | 100 | ||

| Ram Strke Distance | mm | 0-31 | 0-31 | ||

| Working Table | Ball+Brush | Ball+Brush | |||

| Number of sheet clamps | pcs | 3 | 3 | ||

| Power Supply | KVA | 26 | 38 | ||

| 1250*2500*2.3mm | 100% | ||||

| 1250*2500*3mm | 75% | 39m55 s | |||

| Voltage | V | 220/380/410/440 | 220/380/410/440 | ||

| Air supply | NL/min | 250 | 250 | ||

| Air press | bar | 5 | 5 | ||

| Machine Dimensions(L*W*H) | mm | 5105*4690*2210 | 5180*4805*2240 | ||

| Machine net weight(Approx) | kg | 13500 | 14000 | ||

| CNC controller | FANUC Oi-PF | FANUC Oi-PF | |||

| Ram memory | KB | 512 | 512 | ||

| Serial interface | RS232/RJ45/PCMCIA | RS232/RJ45/PCMCIA | |||

| CNC controller | mm | ±0.1 | ±0.1 | ||

| Reposition accuracy | mm | 0.05 | 0.05 | ||

- Specifications are subjects to change without prior notice

- Acceleration/deceleration rate of x/y-axis are dependent on weight of maerials

- Punch speed depends on processing conditions,stroke length,acceleration/deceleration rage of axes speeds.

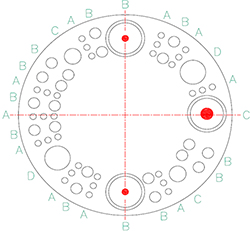

Station Arrangement

X23 |

||

| 57 stations | ||

|---|---|---|

| Type | Specification | Q' ty |

| A | 1/2" | 30 |

| B | 1 1/4" | 20 |

| C | 2" | 2 |

| D | 3 1/2" | 2 |

| Auto Index | ||

| B | 1 1/4" | 2 |

| C | 2" | 1 |

| 57 | ||

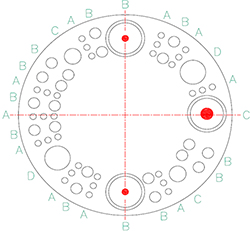

X23+

|

||

| 57 stations | ||

|---|---|---|

| Type | Specification | Q' ty |

| A | 1/2" | 30 |

| B | 1 1/4" | 20 |

| C | 2" | 2 |

| D | 3 1/2" | 2 |

| Auto Index | ||

| B | 1 1/4" | 2 |

| C | 2" | 1 |

| 57 | ||

Layout