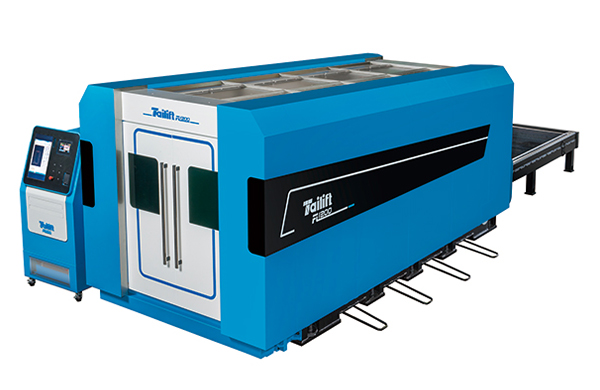

TL Series-Classic (Full Splash Cover with Exchange Table Cutting Machine)

TL4020

- User friendly

- Fast cutting speed, low operating cost and fast return on investment.

- Auto Edge finding. Effectively used in big sheets.

- The electric energy conversion heat energy conversion rate is high, and an effective power saving effect is achieved.

- Low Maintenance. without adjustments of light path and reflect lens, no service requirements.

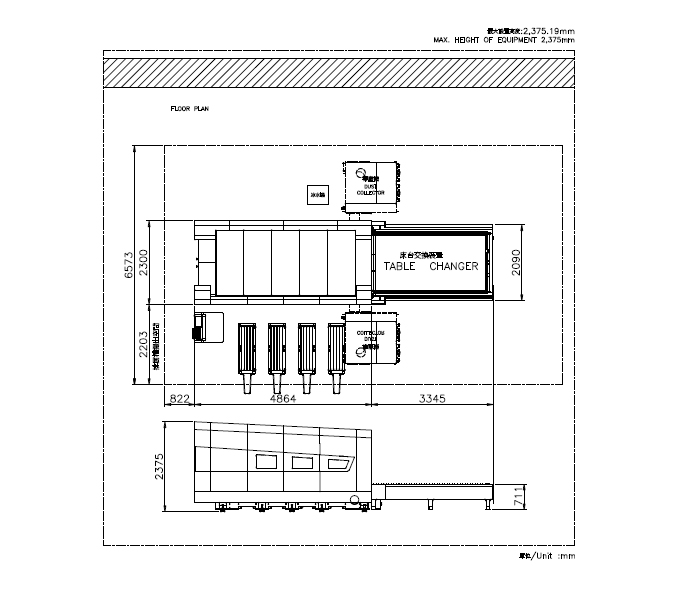

- Closed Frame Base with Gantry Type (Dual-Drive) Integrated Servo Control System to Increase Working Speed and Efficiency.

- Double Working Table Saves Loading/Unloading Time and Increase Productivity.

- Full Covered Machine Body with OD6+ Fiber Protection Safety Glass Window Ensure the Operator Safety and Effectively controls the Laser Radiation in the Environments, Good Light Probation.