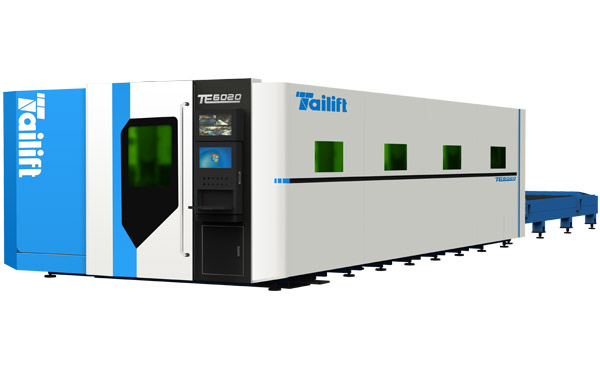

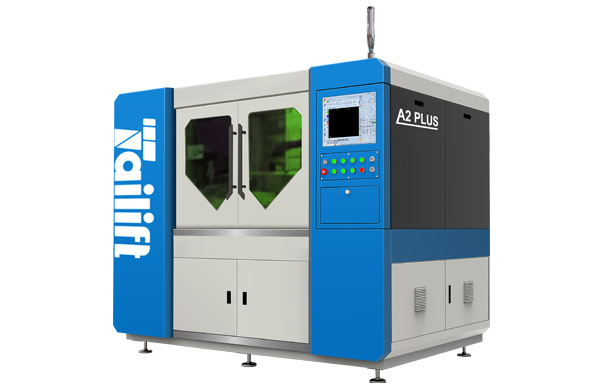

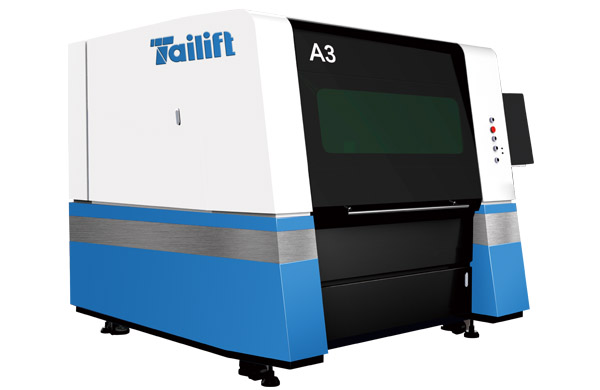

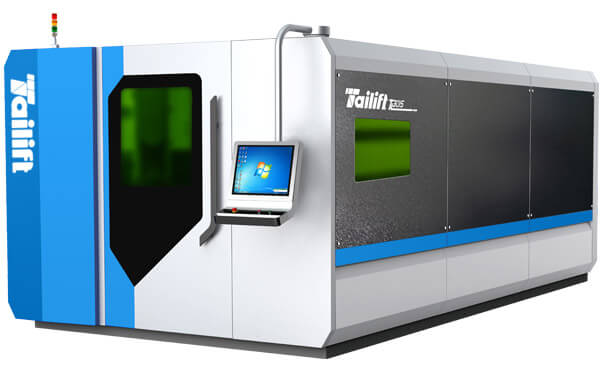

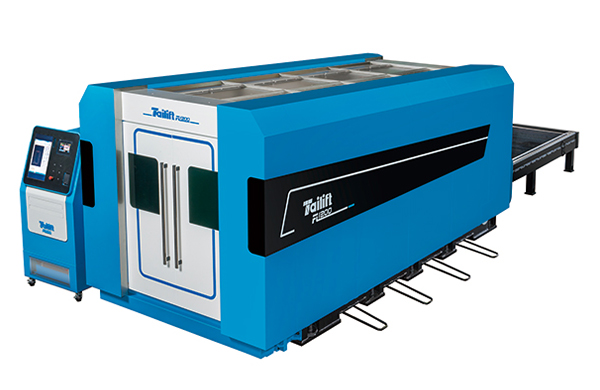

Tailift Laser Cutting Equipment

Taiwan Laser Cutting Equipment Supplier: Tailift

Looking for a reliable laser cutting equipment supplier to meet your precision metal fabrication needs? Tailift is your best partner for advanced metal laser cutting equipment engineered for accuracy, speed, and durability. With over four decades of experience in industrial machinery and sheet metal solutions, we provide powerful laser systems that help manufacturers boost productivity and stay competitive in today’s demanding markets.

As a globally trusted laser cutting equipment supplier, we not only deliver machines but also comprehensive technical support, training, and customization services to meet your production goals.

Why Choose Tailift Laser Cutting Machines?

Our laser cutting machines are designed for a wide range of metal materials, ensuring clean, fast, and highly accurate cuts. Whether you’re working on high-volume production or customized jobs, Tailift machines deliver consistent performance with minimal downtime.

Key Features of Tailift Metal Laser Cutting Equipment:

- Fiber laser sources from leading brands (IPG, Raycus, Max)

- Automatic sheet loading and unloading systems

- High-speed linear motor and gantry designs

- Intuitive user interface with real-time monitoring

Recommended Metal Laser Cutting Equipment

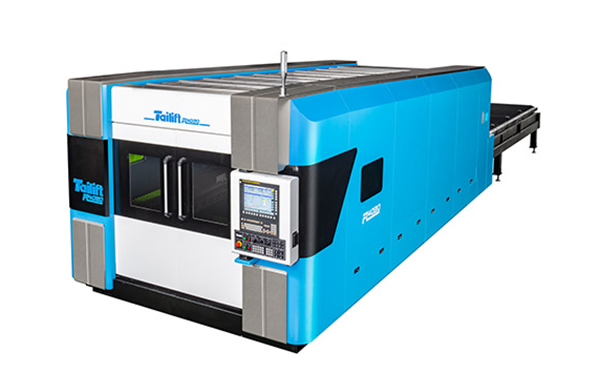

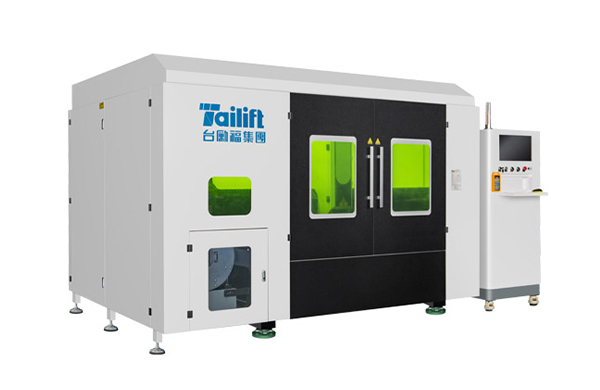

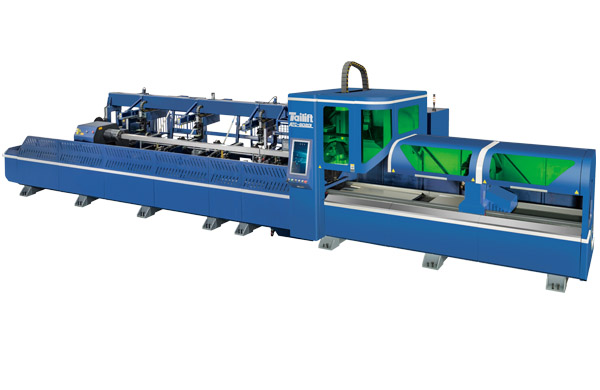

TE12025 Model: Equipped with a high-power laser system capable of up to 40,000 watts, ideal for cutting through thick and heavy-duty metal materials with precision and ease.

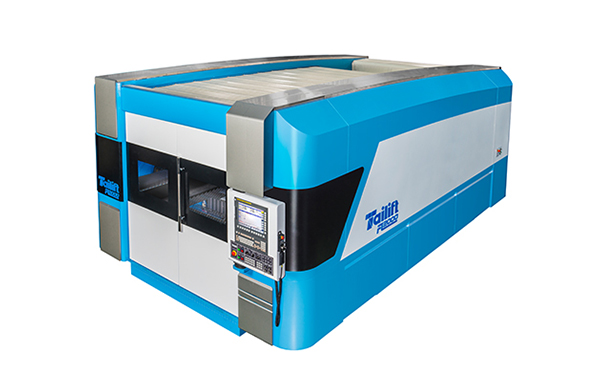

TL1515C Model: Designed with full splash protection, OD6-grade fiber optic safety glasses, and emergency stop switches, ensuring safe operation in demanding industrial environments.

| Machining range(X*Y) | 1500*3000 |

| Travel(X*Y*Z) | 1525*2050*150 |

| Machining range(X*Y) | 2000*4000 |

| Travel(X*Y*Z) | 2050*4050*200 |

| Machining range(X*Y) | 2000*6000 |

| Travel(X*Y*Z) | 2015*6050*200 |

| Machining range(X*Y) | 3050*1525 |

| Travel(X*Y*Z) | 3100*1550*100 |

Frequently Asked Questions

A: Our machines can cut a wide variety of metals, including carbon steel, stainless steel, aluminum, brass, and copper. The cutting quality and speed may vary depending on the material thickness and the laser power selected.

A: Fiber lasers offer faster speeds, lower maintenance, and better energy efficiency, especially for thin to medium-thick metals.

A: It depends on the type and thickness of metal you plan to cut. For example, 1kW–3kW is ideal for thinner sheets (up to 6mm), while 6kW–15kW is suitable for thicker and high-strength metals. Contact our technical team for personalized guidance.

A: With proper maintenance, our systems can operate reliably for over 10 years.

A: Absolutely. We offer automation options such as robotic arms, conveyors, and smart nesting software to streamline your metal fabrication workflow.

A: Tailift laser cutting machines are manufactured to meet CE, ISO, and other international standards, ensuring safety, reliability, and quality.

A: Yes. As a full-service laser cutting equipment supplier, Tailift offers global support that includes installation, training, troubleshooting, and spare parts delivery. Our team ensures your machine operates at peak performance.

Ready to upgrade your metal fabrication process?

Contact Tailift today, your trusted laser cutting equipment supplier, and discover how our advanced metal laser cutting equipment can transform your production capabilities.