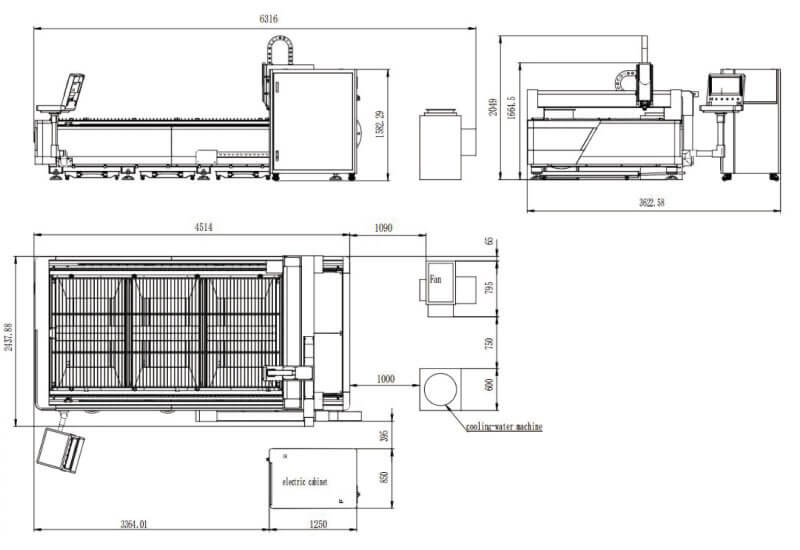

A3015 FIBER LASER CUTTING MACHINE

Fiber laser cutting machines, model A3015, are a revolutionary tool in the manufacturing industry, offering unparalleled precision, speed, and accuracy. The machine employs a high-powered laser beam generated by a solid-state laser and delivered through a fiber optic cable. This advanced technology allows for the cutting of a wide range of metals, including mild steel, stainless steel, aluminum, and brass. As a leading fiber laser metal cutting machine manufacturer, Tailift ensures that our machines meet the highest standards of performance and reliability. With over 20 years of experience in laser cutting technology, we provide solutions that cater to various industries, from automotive to aerospace and beyond.

Why Choose Tailift Fiber Laser Metal Cutting Machines?

Tailift fiber laser cutting machines are designed to offer several significant advantages to users. Firstly, the machine's flatness and accuracy are guaranteed for long-term use, ensuring consistent performance. Our fiber laser cutting machines are equipped with high-performance servo motors that ensure low energy consumption, making them both efficient and cost-effective. Additionally, the high-pressure air cutting capability enhances cutting speed and quality. The CYPCUT controller, known for its high market share, provides a user-friendly interface that simplifies operation. These features, combined with our commitment to quality, make Tailift a trusted fiber laser metal cutting machines manufacturer.

Structural Integrity and Safety Features

The structural integrity of A3015 fiber laser metal cutting machines is unmatched. Our steel beams are made from spliced and welded steel plates, providing high rigidity and long-term accuracy. This makes our machines particularly suitable for large-span floor-rail laser cutting applications. One end of the beam features a special floating structure that ensures long-term operational stability. All debris and waste material are captured in a removable tray, making it easy to maintain a clean and safe work environment.

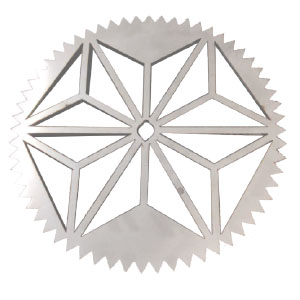

Reliable Fiber Laser Cutting Solutions for Complex Parts

Fiber laser cutters are incredibly versatile and are used to produce a wide range of products, including automotive components, aircraft parts, electronic components, signage, architectural features, and artistic pieces. Tailift fiber laser cutting machines are designed to be versatile, reliable, and easy to use, making them the perfect choice for businesses of all sizes. The latest fiber laser, cutting head, and servo-driven motor technology ensure that every cut is as precise as the last, providing optimum precision and repeatability. Whether you are in the automotive, aerospace, or construction industry, Tailift fiber laser cutting machines offer the precision and reliability you need to create highly detailed parts and components.

Contact us without hesitation or explore more Laser Sheet Metal Cutting Machines now!