Electro Servo

ES23x

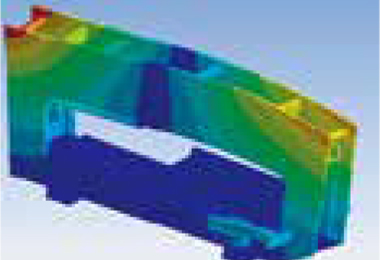

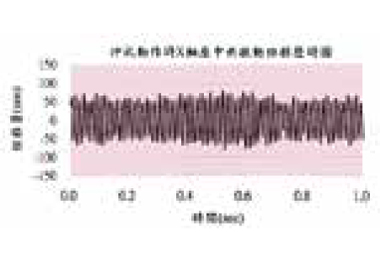

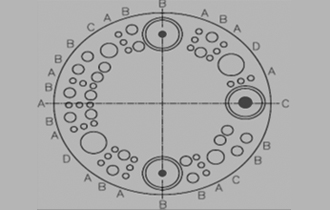

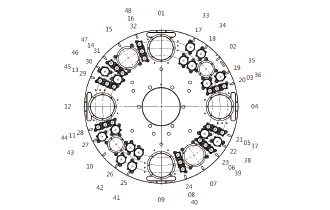

Tailift’s newly launched, ES23X, AC Servo drive and Numerical Control Technology. Featured with HIGH SPEED, HIGH PRECISION, ENERGY SAVING, AND LOW NOISE. Equipped over-load protection, ES23X is an effective implement for thinner sheet metal. ES23x combined with processing abilities of PUNCHING, FORMING, ROLLER CUTTING AND TAPPING, an all-in-one machine. The integration assembly reduces floor space requirements effectively. Low average electricity consumption, energy-saving, eliminating the hydraulic. This ECO friendly product is the major milestone for Tailift’s R&D.